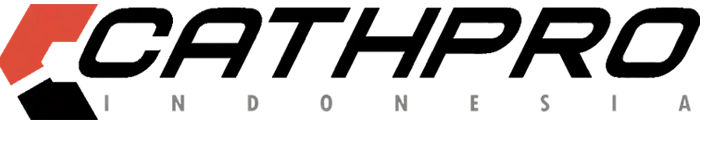

When metal structures face constant exposure to harsh environments, corrosion becomes an invisible enemy that costs industries billions annually. Proper corrosion control system installation isn’t just a preventive measure—it’s an investment that protects your assets, ensures safety, and maintains operational efficiency. Understanding corrosion protection methods and implementing the right corrosion prevention system can mean the difference between decades of reliable service and catastrophic failure.

Understanding Corrosion and Its Impact

What Causes Corrosion?

Corrosion occurs when metals react with their environment through electrochemical processes. Moisture, oxygen, salt, and chemical exposure accelerate this natural degradation. Different corrosion protection methods exist because various factors trigger corrosion—from simple atmospheric exposure to complex galvanic reactions between dissimilar metals.

Temperature fluctuations, pH levels, and microbial activity further complicate the corrosion process. Marine environments pose particular challenges with salt spray and constant moisture. Industrial facilities face chemical exposure and high-temperature conditions that demand specialized protection strategies.

The Cost of Corrosion in Industry

The global cost of corrosion exceeds $2.5 trillion annually, representing roughly 3.4% of global GDP. Pipeline failures alone account for billions in environmental cleanup and lost product. Offshore platforms spend approximately 20-30% of maintenance budgets on corrosion-related issues.

Storage tanks experience failure rates that double without proper protection systems. Refineries report that corrosion causes 50% of all equipment failures. These statistics underscore why investing in quality protection systems delivers significant ROI through extended asset life and reduced downtime.

Corrosion Control System Installation: Step-by-Step Approach

Site Assessment and Risk Analysis

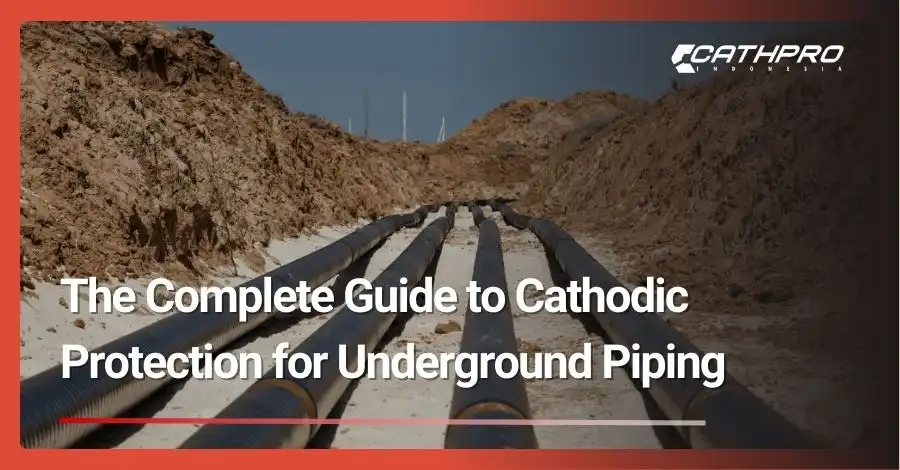

Successful corrosion control system installation begins with comprehensive site evaluation. Engineers analyze soil resistivity, water chemistry, and environmental conditions to determine corrosion risk levels. Pipeline corrosion protection requires special attention to coating holidays, stray currents, and interference from nearby structures.

Risk assessment identifies critical areas needing immediate protection. High-consequence zones near populated areas or environmentally sensitive regions receive priority. Documentation of existing conditions establishes baseline measurements for future monitoring.

Proper assessment saves money by avoiding over-protection in low-risk areas while ensuring adequate coverage where needed most. This targeted approach optimizes resource allocation and system effectiveness.

Selecting the Right Protection Method

Choosing between cathodic protection, protective coatings, and corrosion inhibitors depends on specific application requirements. Cathodic protection installation works excellently for buried pipelines and marine structures. Impressed current systems suit large structures with high current demands, while sacrificial anodes excel in confined spaces.

Coating systems provide the first line of defense, reducing cathodic protection current requirements by 95%. Fusion-bonded epoxy excels for pipelines, while specialized marine coatings protect offshore assets. Inhibitors complement other methods, particularly in closed-loop systems.

Cost-benefit analysis guides selection decisions. Initial investment, maintenance requirements, and expected service life influence the optimal choice. Many projects benefit from hybrid approaches combining multiple protection methods.

Installation and Quality Standards

Professional installation ensures your corrosion prevention system performs as designed. Certified installers follow strict procedures for surface preparation, coating application, and electrical connections. Quality control measures include holiday detection, adhesion testing, and continuity verification.

Proper grounding and isolation prevent interference between systems. Anode placement calculations ensure uniform current distribution. Test stations enable ongoing performance monitoring throughout the system’s life.

Documentation throughout installation creates valuable reference materials for future maintenance. As-built drawings, test results, and commissioning reports establish system baselines and compliance records.

Best Practices for Effective Corrosion Control

Compliance with Industry Standards

Following NACE, ISO, and API standards ensures reliable protection and regulatory compliance. NACE SP0169 guides pipeline cathodic protection design, while ISO 12944 addresses coating systems. API 651 covers tank bottom cathodic protection requirements.

Standards provide proven methodologies developed through decades of industry experience. They establish minimum requirements while allowing flexibility for site-specific conditions. Regular standard updates incorporate new technologies and lessons learned from field experience.

Certification programs validate installer competence and system performance. Third-party inspections verify compliance and identify potential issues before they become problems.

Combining Methods

Integrated protection strategies deliver superior results compared to single-method approaches. Cathodic protection and coatings work synergistically—coatings reduce current demand while CP protects coating defects. Real-time monitoring systems detect changes requiring intervention.

Successful combinations require careful design to prevent conflicts between methods. Coating selection must consider cathodic disbondment resistance. Inhibitor programs complement rather than interfere with electrochemical protection.

System integration planning during design phases prevents costly retrofits. Coordinated maintenance schedules maximize protection while minimizing operational disruption.

Offshore and Marine Applications

Offshore corrosion control faces unique challenges from aggressive marine environments. Splash zones experience accelerated attack from alternating wet-dry cycles. Subsea structures require robust systems capable of decades-long operation without maintenance access.

Platform legs utilize heavyweight bracelet anodes or impressed current systems. Ballast tanks combine coatings with sacrificial anodes for redundant protection. Monitoring systems track protection levels despite challenging access conditions.

Marine growth affects current distribution and increases maintenance requirements. Design calculations account for calcareous deposit formation that reduces current demand over time. Regular inspections identify anode consumption rates and coating degradation patterns.

Monitoring and Maintenance After Installation

Regular inspections ensure continued protection effectiveness throughout system life. Annual surveys measure protection potentials and identify areas needing attention. Close interval surveys provide detailed protection level mapping for critical assets.

Preventive maintenance extends system life while reducing total ownership costs. Anode replacement before complete consumption prevents protection gaps. Coating repairs address defects before extensive damage occurs.

Industrial corrosion solutions increasingly incorporate remote monitoring capabilities. Automated data collection enables predictive maintenance strategies. Cloud-based platforms provide real-time alerts when parameters exceed acceptable ranges. One refinery reduced corrosion-related failures by 75% through proactive monitoring and maintenance programs.

Industries That Rely on Corrosion Control Systems

Pipeline operators protect thousands of miles of buried infrastructure carrying oil, gas, and water. Transmission lines utilize sophisticated cathodic protection networks monitored from central control rooms. Distribution systems employ simpler but equally effective protection strategies.

Offshore structures including drilling platforms, FPSOs, and wind turbines require comprehensive protection programs. Ships implement impressed current systems protecting hulls during decades of service. Port facilities protect steel pilings and sheet pile walls from accelerated low-water corrosion.

Storage tanks at refineries and terminals utilize bottom cathodic protection preventing soil-side corrosion. Chemical plants protect process equipment from aggressive product exposure. Water treatment facilities prevent infrastructure degradation that could compromise water quality.

Conclusion

Effective corrosion control system installation requires careful planning, quality implementation, and ongoing maintenance commitment. The investment in proper corrosion prevention systems pays dividends through extended asset life, improved safety, and reduced operational costs. Whether protecting pipelines, offshore platforms, or storage facilities, following industry best practices ensures long-term success.

Don’t wait for damage to disrupt your operations. Contact Cathpro Indonesia’s experienced, innovative prevention specialists today to assess your protection needs and develop a comprehensive strategy tailored to your specific needs.

Your infrastructure deserves the protection that only a properly designed and installed corrosion control system can provide.